Image result for clt building level one floor detail Timber architecture, Architecture

Technical Study: CLT Construction. Cross-laminated timber (CLT) is becoming an increasingly popular construction method within the UK due its sustainable credentials, speed of erection and low structural weight. CLT is pre-fabricated in the factory by glueing multiple layers of timber together in perpendicular layers to form large panels that.

CLT Mirck Architecture

CLT Factory invests heavily in R&D, working together with scientists and engineers - as well as traditional carpenters and cabinet-makers to bring innovation to the growing field of timber raw structures, modular buildings and both private and public buildings. Our Klik-Klik Wall System allows unprecedented flexibility for small teams of.

CLT wand, vloer en dakelementen van Heko Spanten

Are you interested in learning more about CLT, a type of mass timber construction that offers many benefits for sustainable and efficient building? Download the free guide for architects and engineers, created by INBO, a leading Dutch design firm with expertise in wood construction. The guide covers the basics of CLT, its applications, design principles, and technical aspects.

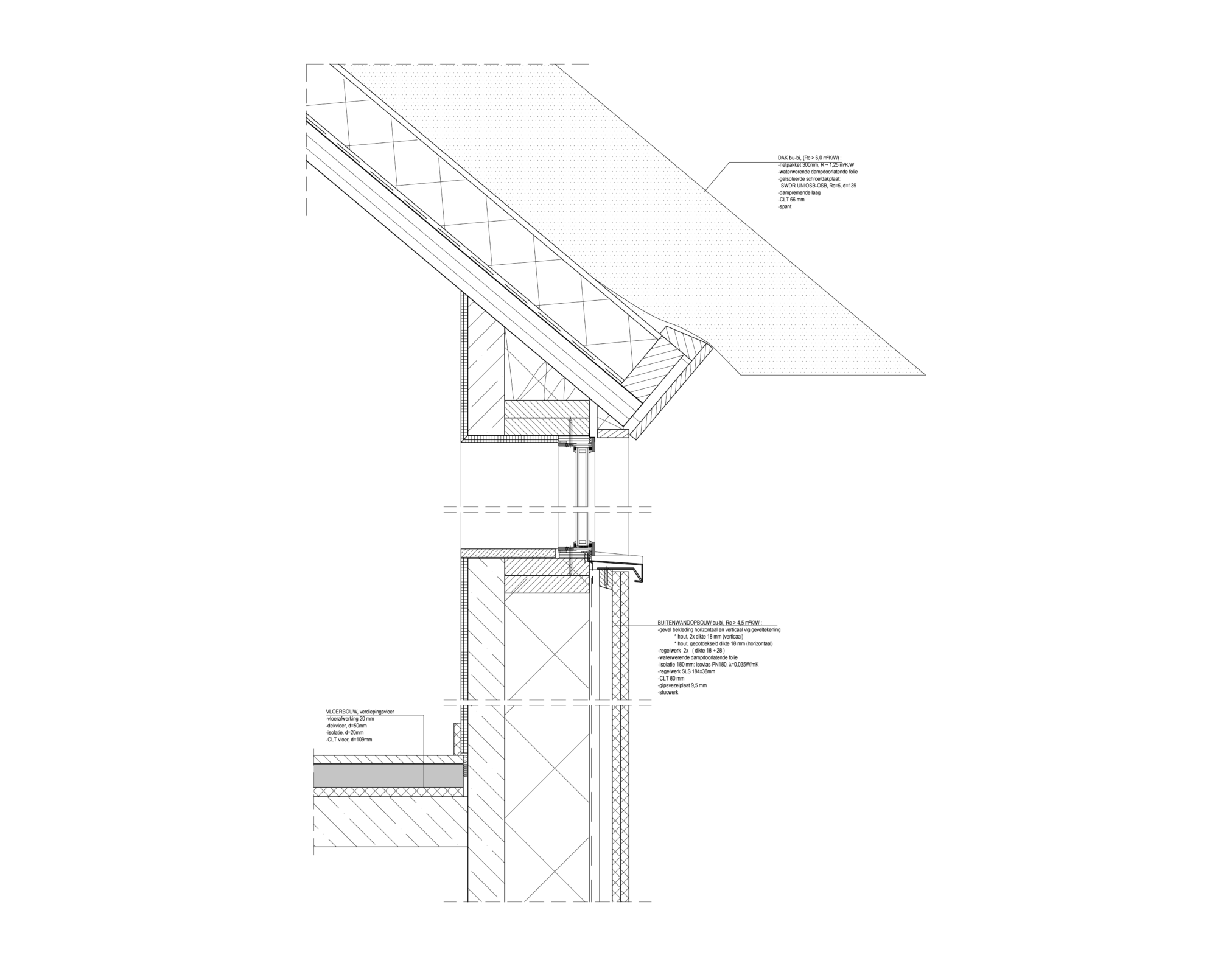

Clt Wall To Floor Detail

Cross-laminated timber (CLT) is a large-scale, prefabricated, solid engineered wood panel. Lightweight yet very strong, with superior acoustic, fire, seismic and thermal performance, CLT is also fast and easy to install, generating almost no waste onsite. CLT offers design flexibility and low environmental impacts.

CLTconstructies essentiële punten om in acht te nemen

Because CLT is made of wood, it can store carbon during the building's lifetime and even capture additional carbon. In fact, researchers have found that a hybrid, mid-rise CLT commercial building provided a 15-26% reduction in global warming potential, depending on the building design. Kelley said wood isn't as energy-intensive as steel and.

Clt Wall To Floor Detail

A class of CLT panels determined by the combination of grades of laminations in the longitudinal and transverse layers EDGE The narrow face of a panel that exposes the ends or narrow faces of the laminations EDGEWISE BENDING Bending of CLT under loads applied to the panel edge creating in-plane bending and edgewise shear, also known as in-plane

View Architecture Clt Construction Details Images Edward M. Barton

New Details. This month we have put together a selection of cross laminated timber (CLT) details. CLT is a growing construction method that demonstrates a number of benefits, including good structural properties, low impact on the environment, fast construction with off site preparation and good fire performance to name a few. This set of CLT.

Reaching New Heights

If the CLT is reused after a shaving round (marginal CO2 emissions), the CO2 is locked in for another lifetime, which can be further extended through cascading. The i gures below are based on generic sec-tor-based EPDs for CLT and concrete (C35/45, excluding CO2 emissions of steel reinforcements) published in the German IBU EPD database.108 109

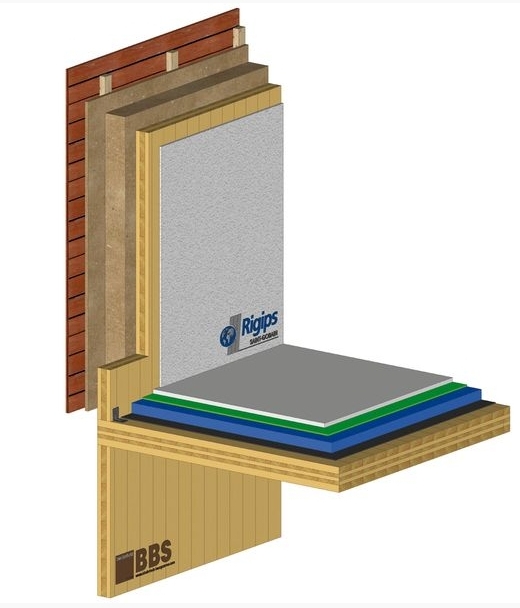

CLT FLOOR TO BALCONY Ecosia Images Prefab Cabins, Prefab Homes, Prefab Buildings, Clt

In detail: Cross-laminated timber. Cross-laminated timber (CLT) is a structural building product composed of an odd number of adhesively bonded layers of timber, where each layer is placed at a right angle in relation to the previous one. This method creates a product with a high dimensional stability and load-bearing capacity, and advantages.

Image result for Section detail services ceiling timber Floor detail, Timber ceiling

CLT is an engineered wood panel product that was developed in Europe in the 1970s and has been in continuous development ever since, particularly. In this detail the solid blocks and ring beam should be an engineered timber product such as laminated veneer lumber (LVL) or laminated strand lumber (LSL) in order to minimise

Opbouw van SIPs gevel en CLT vloer YouTube

CLT (Cross Laminated Timber), ofwel kruislaaghout is een innovatief houtbouwproduct. De sterke, massief houten constructieplaten zijn opgebouwd uit drie of meer lagen kruislings verlijmde vuren lamellen. Ze worden vooral gebruikt als vloer-, wand- of dakelementen en zijn een volwaardige vervanging voor metselwerk of beton.

DL214 CLT Intermediate Floor Detail

Clt-Concrete slab details. Concrete slabs can be prefabricated or cast on site according to the construction method used in the CLT-concrete system. In the onsite casting system, a wet concrete slab is cast and cured on the dry timber system.. CLT-concrete dance floor at Thomas Clarkson School, UK [16]. 4.2. Pedestrian bridge.

CLT

The CLT-concrete system had 3-5 times higher strength capacity and optimal mechanical and seismic performance than the conventional CLT floor [4]. Another study [25] reported that the load-carrying capacity was increased three-fold, and the flexural rigidity increased up to six-fold higher than the concrete or timber floor systems.

CLT wand, vloer en dakelementen van Heko Spanten

Cross-laminated timber (CLT) is a mass timber product that can replace concrete and steel in modern construction. As buildings become more sustainable and timber structures grow larger, CLT has become a popular solution for floors, roofs, walls, and stairs due to its strength, appearance, and versatility. Photo: Belén Imaz/ÁBATON Arquitectura/Madergia

Detail Library New Details March 2023 CLT Details

CLT wand-, vloer- en dakelementen. CLT = Cross Lamineted Timber = kruislings verlijmde houten platen, het wordt steeds vaker gebruikt in de bouw. Dat heeft alles te maken met de vele voordelen die dit materiaal biedt. Kruislaaghout bestaat uit platen van minimaal 3 kruislings verlijmde lamellen. Dankzij deze samenstelling hebben omstandigheden.

Clt Floor Detail 60bd Swiss

CLT panels consist of layered lumber boards (usually three, five, or seven) stacked crosswise at 90-degree angles and glued into place. Finger joints and structural adhesive connect the boards. Board thickness typically varies between 5/8 inch to 2 inches, with board width ranging from 2.4 to 9.5 inches.The panels can be manufactured at custom dimensions, though transportation restrictions.